In the last 20 years, there was a revolution in the ID card industry when desktop ID card printers were introduced. This allowed security and IT teams to meet compliance requirements to personalize and print high-quality plastic ID badges on-site with various embedded technologies, including RFID and barcodes.

This article will help you better understand how an ID card is printed, and what type of ID card printing technology will work best for your needs.

How An ID Card is Printed

Personalized color ID cards are printed by infusing dye from a film ribbon into the plastic surface of an ID badge. ID card printers use a roll of semi-opaque ID card printer ribbon made up of a repeating series of Yellow (Y), Magenta (M), Cyan (C), Black (K), and Overcoat (O) panels to print ID cards.

YMC panels contain thermally sensitive dyes that when combined in varying amounts, create any color spectrum, from white (no dye transferred) to black (full transfer of each of the three dyes). The Black and Clear panels operate in a process called “mass transfer”, in which all of the material (in this case a plastic resin rather than a dye) is transferred when the carrier ribbon reaches the required transfer temperature. Black resin applies dense black text and barcodes on top of YMC color images, and the Clear panel adds a protective overcoat layer over the entire printed image.

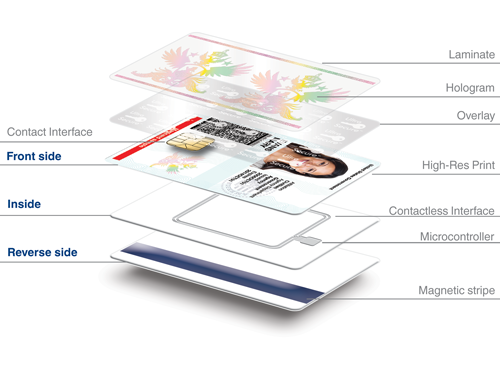

For users who need extra ID card protection, a lamination layer can be added on top of an ID card, after the regular color or monochrome printing process. ID card overlaminates are normally a 0.6 mil or a 1 mil thick layer of polyester. Lamination protects the ID card from scratching and wear and tear and comes with options for clear, holographic, and custom hologram film. Lamination is recommended for high-wear usages ID cards, such as those used in secure access control applications with HID prox, iclass, or Seos in addition to Mifare, DESFire EV2, or any type of ID badge exposed to daily swiping in a physical environment.

Direct-to-card vs. Reverse Transfer Printing

There are two primary methods that ID card printers use to personalize plastic ID cards: direct-to-card (also known as dye-sublimation), and reverse-transfer (sometimes referred to as retransfer) ID card printing. Both methods reliably create high-quality printed ID cards but differ in price, speed, and ID card durability.

Direct-to-Card Printing

Direct-to-card ID card printing, also known as dye-sublimation or dye-diffusion ID card printing is the most common method used to print images directly onto ID card surfaces. With direct-to-card printing, the ID card printer transfers color directly to a blank ID card by heating a special ribbon beneath the thermal printhead. The heat from the printhead causes the ink in the ribbon to vaporize into a gas, which then diffuses into the surface of the ID card, where it solidifies, or sublimates, into a solid, resulting in a durable color pigmentation on the white surface of the ID card, that resists scratching and fading.

Since the ID card printer can only lay down one color at a time, the dye-sublimation process is repeated for each YMCK panel until a complete, colored image is formed on the ID card. As a final step, the printer prints an overcoat (O) panel over the entire ID card surface, protecting the card from UV and physical damages. Certain brands of ID card printers can also print a secure watermark onto the surface of ID cards during this step in the ID card printing process.

The benefit of dye-sublimation ID card printing is that it is fast, cheap, and easy to use, and the majority of desktop ID card printers on the market today use dye-sublimation technology, proving it to be straightforward and reliable solution.

Reverse Transfer ID Card Printing

Reverse transfer ID card printing is a high-quality print process that functions by first transferring ink from a YMCK dye film onto a clear film. Once it contains all the ink, the clear film is then laminated onto the ID card. By placing the YMCK dye film onto a clear film instead of directly onto the surface of the ID card, true edge-to-edge printing with deeper color saturation and better resolution than the dye-sublimation process is possible.

To make reverse transfer printed ID cards more durable, an additional overlaminate layer can be added to the card for greater protection against scratches or other forms of wear and tear damage. Many organizations place a holographic feature onto the overlaminate to add greater visual security to their ID cards. For the highest level of security, a custom holographic ID card overlaminate can be designed and applied to ID cards.

ADVANTIDGE works with IT and security teams who need access to industry experts for secure ID card printing, visitor management, 2FA multi-factor authentication, and physical access control systems. We bring a consultative approach to our conversations to be sure you have a solution that meets compliance and exceeds your expectations for service.